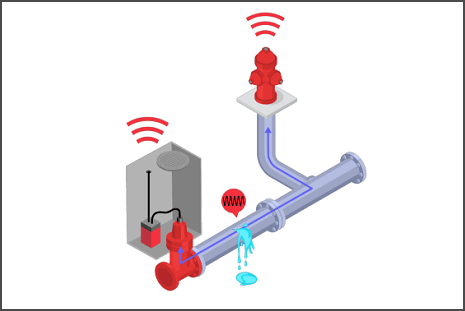

Leak monitoring provides a suite of tools and methodologies that help utilities evaluate and manage water loss in a more effective manner. Having the ability to be proactive instead of reactive helps utilities optimize their operations by identifying leaks earlier, monitoring the progression of leaks, and prioritizing repair. Non-Revenue Water has traditionally been the driver for these types of technologies, but we are starting to see more environmental concerns, along with risk mitigation becoming more important. Click on the video above to learn more from Corey Keefer and Asha Budhall on how utilities can optimize the efficiencies of their water distribution network with the latest in leak detection.

Click here for more information on leak detection.

Mueller International has had another great run of exhibitions lately to meet with our customers and showcase our global solutions. Recent events include IWA (Denmark), WETEX (Dubai), Perumin (Peru), and the Water Industry Asset Management Conference (UK) – spanning coverage across three key continents. The shows represented great opportunities to share the international brand portfolio across a wide variety of industries and applications looking for world-class and innovative water product solutions.

Click here for the Mueller International website.for the Mueller International website.

George Lacefield is the Senior Training Manager with Mueller. He has conducted over 800 courses for utility workers, contractors, distributors, and employees. Along with a good sense of humor, George really knows his stuff when it comes to hydrants, as you will see in this video.

Click here for more information on the Super Centurion fire hydrant.

Mueller Network-as-a-Service (NaaS) Advanced Metering Infrastructure (AMI) solution helps water utilities improve service levels and realize operational safety and efficiencies, through rich consumption data and remote management. This solution provides a full range of secure connectivity options to maximize wireless coverage across the utility service area.

The Mueller Cellular Node is the latest addition to the Mueller AMI system, it allows water utilities to connect meters to their AMI network where radio communication is not feasible or cost-effective. This NaaS endpoint communicates with encoded water meters, including meters that are already in operation. The agility that comes with this model allows utilities to deploy an AMI network in small areas, or entire distribution networks, without the need for traditional infrastructure and maintenance.

Click here for more information on Mueller NaaS solution.

Mueller was recently hired by an energy performance firm to survey a federal government water distribution network in Ontario to determine if leakage was contributing to unnecessary energy consumption. Approximately 46 km (28.5 miles) of watermains were surveyed using EchoWave® acoustic leak detection to non-invasively detect and pinpoint leaks. Echologics® field technicians set up 222 access points on pipes, valves, and hydrants to attach LeakFinder-ST™ leak correlator sensors.

A total of seven leaks (including hydrant, service piping, and water main leaks) were identified, and one of the leaks on an 8” water main was significantly large. Given that the size of this water main leak was identified to be large, the Echologics team was on site during the leak excavation and repair activities. Upon excavation, it was determined that the circumferential crack on the 200 mm (8”) cast iron water main had an average width of approximately 3 mm (1/8”) and covered over 50% of the circumference of the pipeline. The crack was determined through visual observations as actually being slightly less than 3 mm (1/8”) wide at the edges but approximately 6 mm (1/4") wide at the bottom of the pipe.

The leak was repaired utilizing a stainless-steel repair clamp, which is a standard repair for this type of leak. The water main did not show signs of severe or widespread corrosion. The initial leak size estimate at time of survey for the water main leak was between 297 and 731 LPM (78 - 193 GPM). This range is typical for non-surfacing water main leaks. With additional information on the type of leak (circumferential crack) and the size of the opening, the Echologics team was able to make a more accurate assessment of the leak size using the AWWA M36 manual on water audits and loss control programs, along with operator judgment and adjusting for operating pressure.

Two approaches were utilized; one was to convert the leak opening area to an equivalent size of a circular hole and to utilize the orifice equation to determine the leak flow rate, and the second method was to utilize published literature on average flow rate from cracks to estimate the leak size. The cost of a leak this size was determined to be close to CAD 1 million a year. Large leaks can consume a significant amount of energy by continuously pumping water to maintain desirable water pressure. This also puts unnecessary wear on pumping equipment that is used to keep water flowing that never makes it to the tap.

As water mains are often buried deep, leaks are less likely to surface and can go undetected for several years. As the main artery of the water distribution system, water mains transport huge volumes of water and are often under higher pressure to meet demand over long distances. Consequently, when a leak does occur, the volume of water loss is often greater than on smaller pipes. The best solution for water mains is a permanent leak monitoring system that can find most leaks on a pipeline, including small leaks, before they turn into catastrophic failures.

Click here to learn more about the Leakfinder-ST correlator.

Halifax Water (HW) partnered with Mueller for a performance trial of advanced pressure management and the Sentryx™ Water Intelligence Platform. The pilot program included three phases of implementation.

Phase one served to evaluate the communication and reporting functionality of the pressure loggers as well as the data analytics, notification alarms, and data visualization of Sentryx. A total of three pressure loggers were installed – two single-port pressure recorders within existing air release valve chambers and one triple-port pressure logger to record the inlet, outlet, and control chamber pressure of an existing pressure reducing valve (PRV) station.

HW was able to derive valuable insights about its network that it did not have before and see visually see the data using maps and graphs on Sentryx. Interesting insights included the detection of pressure surges and transients at one of its air valve installations. It is a standard feature of the loggers that they collect statistical data that enables transients to be detected. While HW previously had pressure sensors reporting to SCADA, the Mueller data loggers enabled the utility to monitor pressure and flow at air release valves (ARVs) and other locations without existing power and communications.

In phase two, the PRV was retrofitted with the Advanced Pilot Valve (APV) with the existing PRV pilot system still installed but valved off to allow for back-up control during routine maintenance. A control logger was also connected to the PRV. Utilizing the APV and control logger, the PRV can now be controlled remotely with the new advanced pressure management system.

Once the new pilot proved its ability to regulate and keep a constant outlet pressure, HW moved on to test control using “flow-modulation”. In flow modulation, the PRV outlet pressure is varied based on the actual demand in the DMA. This allows a lower pressure set point at night when demand is low and system head-loss is at its minimum. During peak demands, pressure is increased to overcome system head-loss and ensure sufficient pressure within the DMA. Flow modulation is ideal for lowering pressure in off-peak demands to reduce leakage flows and the occurrence of water main breaks. It also responds quickly to increase pressure at peak demands or for fire flow requirements.

In phase three, rather than setting fixed or timed outlet pressure from the PRV, in Automatic Optimization mode, the system takes in data from the PRV and from a logger placed deeper in the network at which the water utility wants to deliver fixed pressure levels. That position is called the “control point”. All the user needs to do is set the target pressure levels required at the control point by time of day and day of the week. Sentryx does the rest: it receives data from the PRV control logger and the Control Point logger and calculates the optimal control curve to achieve the target pressure. It then adjusts the PRV outlet pressure continuously. The profile is created in the software service, then sent down to the control logger. It takes just 1 week to be confident in its first curve. The curve is automatically re-calculated regularly to account for changes in demand. These may be seasonal or may result from changes in customer usage in that area of the network over time. The system ensures that pressures are maintained at the minimum viable level at all times. This in turn reduces leakage and the likelihood of pipe bursts. This method of optimized pressure management gives HW the highest level of security of supply while reducing NRW loss.

Click here to find out more about Mueller advanced pressure management.

The new EchoShore®-DXe acoustic leak monitoring sensor is a new valve-based sensor that extends the leak monitoring capabilities of the Echologics® EchoShore-DX system. The sensor can attach magnetically to various appurtenances, including valves, boundary boxes, and underground hydrants – and works in tandem with the EchoShore-DX hydrant-based sensors – so utilities can get coverage where they need it.

The sensors performs a scheduled, system-wide correlation to monitor, detect, and locate leaks – even small and growing leaks. The EchoShore-DXe sensors have 10-year battery life and support communications via LTE Cat-M1 and Narrowband Internet of things (NB-IoT) networks. Both the hydrant-based and valve-based sensors work together to provide optimal sensitivity and reliability.

Click here to find out more about the EchoShore-DXe leak monitoring system.

Watch the video above to learn how Mueller is leading the way to efficient operations, responsible sourcing, and the development of sustainable products through the use of C87850 lead-free, silicon-based copper alloy.

Click here to download the white paper on lead-free copper alloys in waterworks applications.

Ozzie Zambrano | Metrology Territory Manager – IL, OH, IN South MI

John Burroughs | Infrastructure Territory Manager – North GA

Michael Callahan | Infrastructure Territory Manager – IA, NB, SD

Cris Salas | Infrastructure Territory Manager - Southern CA (Los Angeles)

Joseph Urcinas | Metrology Territory Manager - NY, NJ, PA

Cordney Pickens | Customer Experience Associate - International

© 2022 MuellerCo., LLC. All Rights Reserved. Mueller refers to one or more of Mueller Water Products, Inc., a Delaware corporation (“MWP”), and its subsidiaries. MWP and each of subsidiaries are legally separate and independent entities when providing products and services. MWP does not provide products or services to third parties. MWP and each of its subsidiaries are liable only for their own acts and omissions and not those of each other.MWP brands include Mueller®️, Echologics®️, Hydro Gate®️, Hydro-Guard®️, Jones®️, Krausz®️, Mi.Net®️, i2O®️, Milliken®️, Pratt®️, Pratt Industrial®️, Singer®️, and U.S. Pipe Valve & Hydrant. Please see www.muellerwp.com/brands to learn more.

Privacy Policy.